Determining the Effect of Chemical and Physical Pretreatments on the Yield and Energy Output of Cellulosic Ethanol from Panicum Virgatum

(1) Rivermont Collegiate, Bettendorf, Iowa, (2) Davenport Wastewater Treatment Plant, Davenport, Iowa

https://doi.org/10.59720/16-046

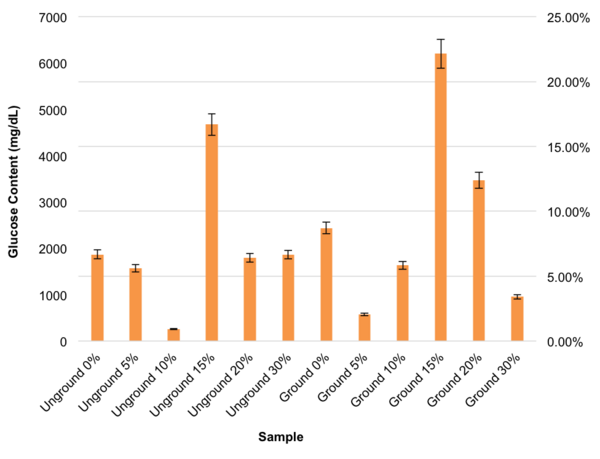

The world needs an energy source that can replace nonrenewable fossil fuels, which release greenhouse gases into the atmosphere. We explored the production of ethanol from switchgrass, a North American grass that is suitable for biofuel production because it contains large amounts of cellulose, a chemical energy that can be used as fuel. Our experiments evaluated whether key factors would increase the efficiency of ethanol production from switchgrass — in other words, which factors produced the highest percentage of ethanol in the final step of distillation. There are four steps to producing ethanol: pretreatment, enzymatic hydrolysis, fermentation, and distillation. We tested two variables: the concentration of potassium hydroxide (KOH) added to the switchgrass during pretreatment and using ground versus unground grass. After adding the KOH to the grass and letting it sit for a week, we balanced the pH and added 5 grams of cellulase to each sample to convert the cellulose to glucose. After 48 hours, we added 10 grams of yeast to turn the glucose into ethanol. In the final step, we distilled all of the samples and measured the percentage of alcohol. Most large-scale production companies use a 30% KOH concentration during their pretreatment procedure, leading us to speculate that a 30% KOH concentration would yield the greatest amount of ethanol. Contrary to this expectation, we found that the sample with 15% KOH content produced the greatest ethanol yield.

This article has been tagged with: