Optimizing 3D printing parameters: Evaluating infill type and layer height effects on tensile fracture force

(1) Arizona College Prep-Oakland Campus, Chandler, Arizona, (2) Arizona State University, Tempe, Arizona

https://doi.org/10.59720/20-083

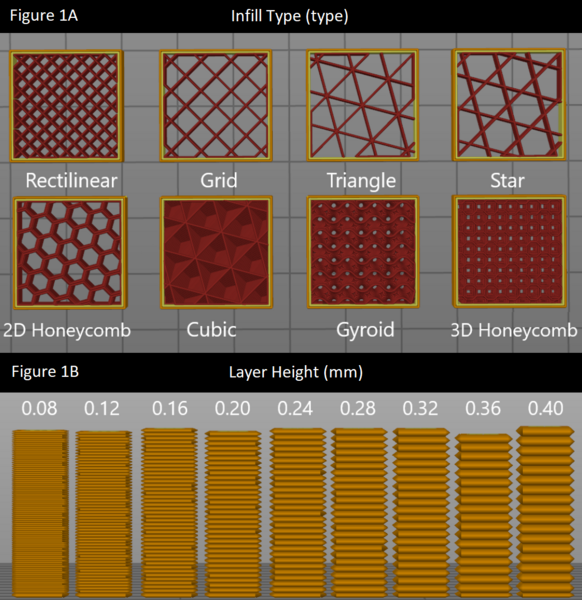

While the concept of 3D printing has existed for decades, only recently has it expanded into our homes, workplaces, and everyday lives. In fact, 3D printing is already being used in a variety of important applications, ranging from prosthetics to automobiles. Nowadays, people can purchase a 3D printer and start 3D printing gadgets from their own homes for under $200. As the concept of 3D printing inevitably continues to develop, it is important that products that are 3D printed are strong and durable, especially if these products are designed to be used frequently or are subject to high loads of stress or pressure. Therefore, this study evaluated the effects of the infill pattern and layer height on the tensile fracture force of tensile testing specimens. To evaluate strength in the XY-directions, we printed tensile testing specimens in the horizontal orientation with different infill patterns and a constant layer height. We hypothesized that the gyroid infill pattern would have the highest tensile strength because it maintains a constant curvature in all directions, therefore having the longest path of least resistance and the maximum tensile strength in a given volume. In order to evaluate strength in the Z-direction, we printed testing specimens in the vertical orientation with varying layer heights and a constant infill pattern. We hypothesized that the lowest layer height of 0.08 mm would yield the highest fracture force because, in the Z-direction, the lowest layer height allows the shapes of extrusions to resemble elongated rectangles instead of ideal circles, which results in larger contact area between the layers. On average, specimens with the gyroid infill pattern exhibited the highest tensile fracture force (mean = 583.14 N) in the XY-directions, and specimens with a layer height of 0.08 mm showed the highest tensile fracture forces in the Z-direction (mean = 526.49 N). Both sets of data supported the hypotheses, showing that the gyroid pattern and 0.08 mm layer height are most practical in terms of strength when 3D printing objects.

This article has been tagged with: